Rock breaking during mining is currently a manual, onsite process. It is only the last few years that the mining industry started to explore the possibilities of automation and offsite control. Our project task is to design a concept for an operator environment for a remote-controlled rockbreaker in mining environment.

10 weeks team project with Yuanrui Li and Justyna Fryczak.

Findings & design direction:

- Impaired vision (visual aid).

- Non-intuitive controls (simplify current systems with partial automation).

- Team work / multitasking (maintain team support structure).

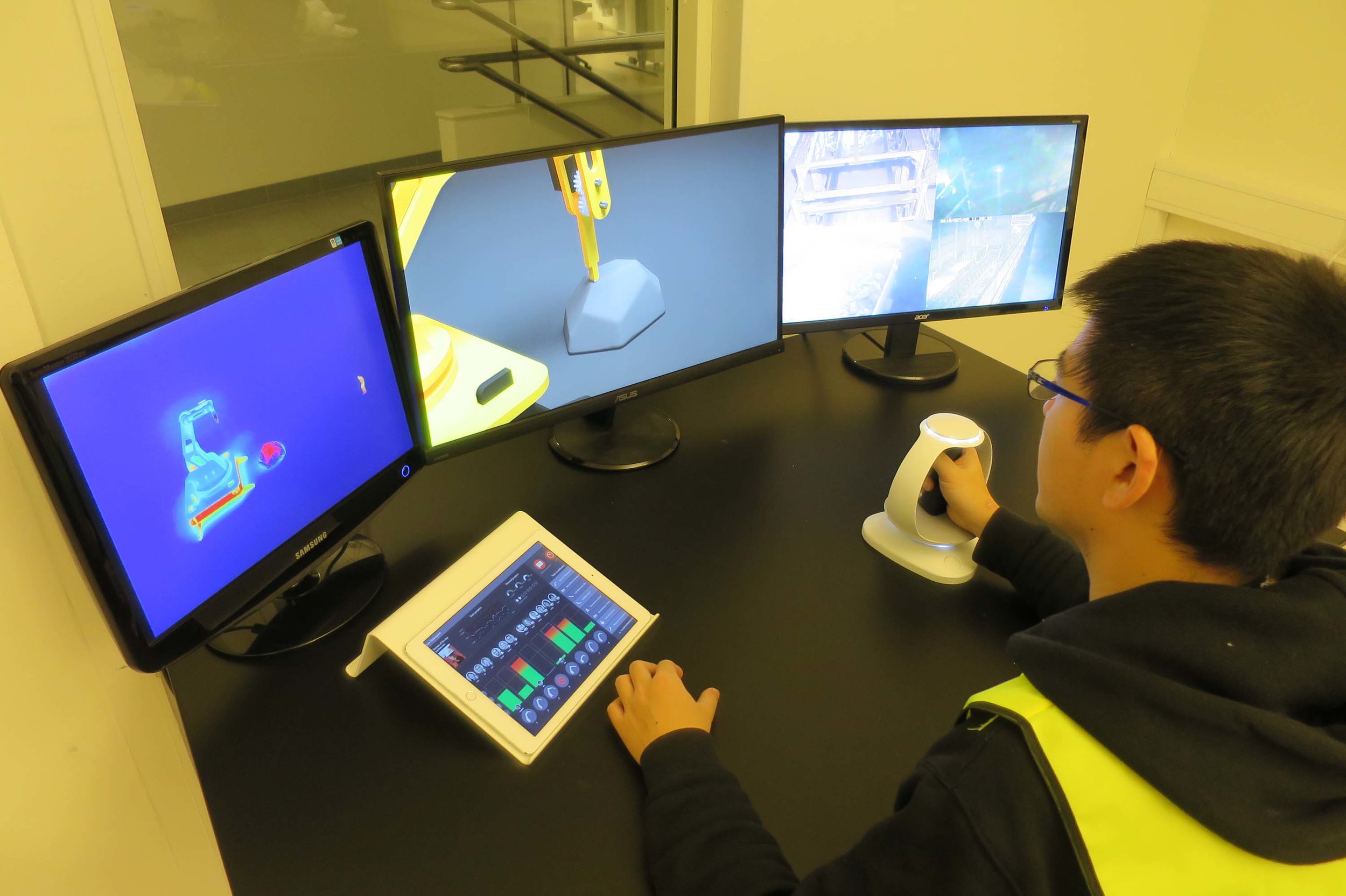

1. Visual assistance

Current system: Cameras placed arbitrarily

Goal: Feeling of looking through a window

Solution: Camera matrix array. View from various angles

Simulated camera matrix view

2. Simplification & partial automation

1. Aiming assistant

An important part of breaking rocks is where to put the hammer tip on the rock, and be perpendicular to the rock before breaking. We provide visual indicators to show 1) when we are perpendicular to the rock, 2) when the hammer tip is approaching the rock and make contact, and 3) when we begin to hammer the rock.

This allows the operator to have very clear visual indication without straining to see or trying to decipher the sound feedback from microphone.

2. Ghost mode

Mechanical rockbreaker moves slower than human operators. This mechanical latency means that the operators have to constantly wait for the machine to "catch up" before the know they are positioned correctly.

Our proposal is to create a digital silhouette of the rockbreaker that moves as fast as the operators do to provide instant location feedback. This "ghost" can help operators position correctly without annoying pause and adjustments.

3. Controller

Our system is semi-autonomous, and the rockbreaker automatically positions itself incorporating boom-tip control. Consolidate controls from two hands to one hand helps to simplify the control and make it more intuitive.

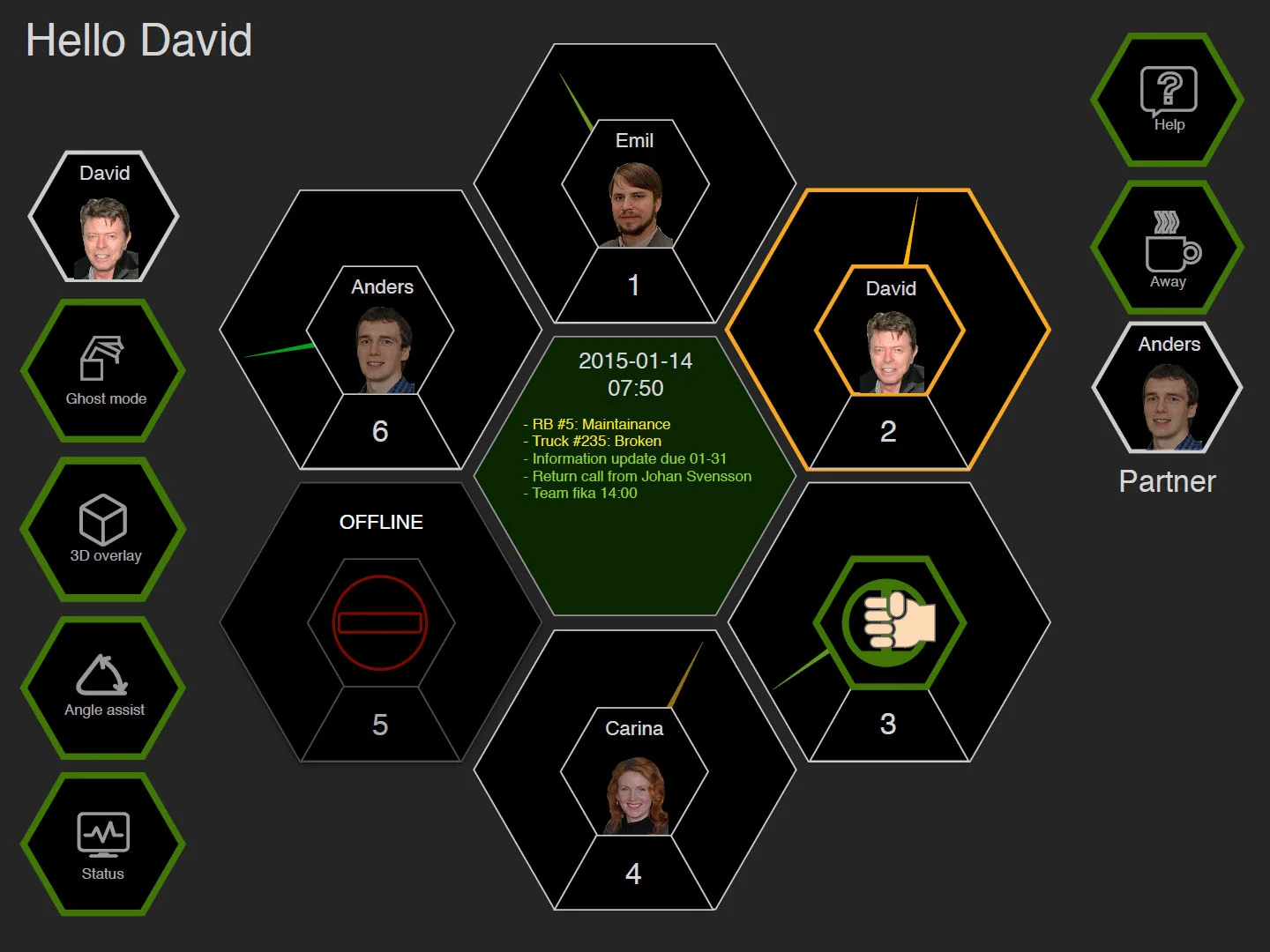

3. Team work environment

Interface shows current status of all rock breakers and status of teammates.

Operator operate with a primary partner daily, and the partner is the first point of contact when help is requested.

Rock breaker operators continue to operate in teams. Each operator is paired with a teammate, their primary partner, each day. When they need help, their primary partner is the go-to person for the day. This maintains a tight knit team that is currently working well for the current in-person setup.

PROCESS

On-site Research

We began with a visit to the Aitik mine in Gällivare to observe and interview the rock breaking operators. Based on the research we collected we found the three areas we wanted t focus on for this project: Improved vision / visualization, control usability, and team work environment.

Analysis

We mapped out what we learned to better understand the process and how it applies to our focus areas.

Prototypes

In the case of control usability, we build various mockups to test our various proposed solutions.

Final